Once the fungi and bacteria are eliminated, the final step is to protect the wood against future fungal penetration (infection) and resulting decay. This is achieved by the use of StoneWood which sets up an enduring, waterproof barricade against fungus. It is once and done. It never needs to be applied again.

White Paper: Killing and Preventing

Fungal Rot in Pressure Treated Wood

Pressure Treated Wood Problems for Homeowners:

At the end of 2003, manufacturers of pressure treated wood and a federal agency entered into an agreement removing the arsenic from pressure treated wood. This may have been a good idea... but unfortunately for homeowners, (and over the objections of the pressure treatment facilities) the manufacturers of PT wood were not given sufficient time to find the proper substitute treatment or time to test the alternatives.

The result has been that pressure treated wood does not resist fungal decay as well today as previously. This has caused decks, docks, porches and various outdoor projects to require maintenance and/or replacement much sooner than previously expected thereby creating dangerous and costly problems.

Up until present, the only solution has been for homeowners to replace the rotting pressure treated wood with new pressure treated wood which in some cases is still subject to the same problems of fungal penetration-infection resulting in decay.

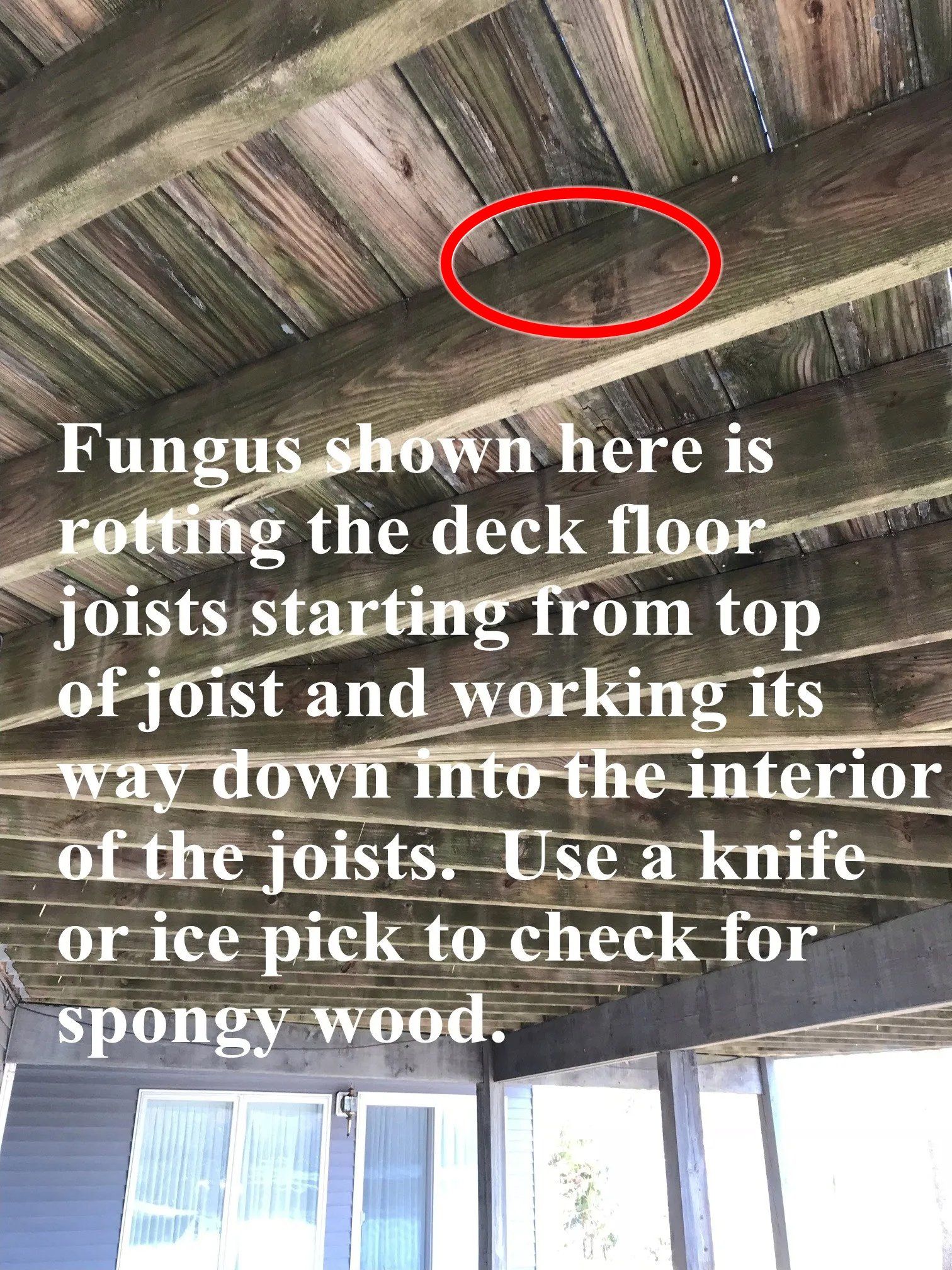

In other cases, homeowners are replacing their PT decking with composite decking not realizing that the fungus that rotted their PT flooring is currently rotting their PT framing. (See photos above and slideshow below for some scary photos.)

This has resulted in an unwanted surprise of floor joists breaking... resulting in people getting hurt and having to demolish the whole deck, including the new composite decking.

How to Test for Pressure Treated Floor Joist Fungal Decay

A visual inspection of the underside of floor joists may disclose fungal rot but more often the decay is internal and has been occurring from the top of the joist down through the internal wood fibers. Use a sharp knife or ice pick near the top of the joists. If the knife encounters spongy wood, there is likely a problem. Carefully and slowly repeat this process along the top of each PT floor joist. If any joists show decay, they will need to be replaced or “sistered” with new joists that have been preserved and protected (we explain the process below).

In many cases, the existing old floor joists are still structurally sound and only need the fungus killed and the wood protected. You can really only confirm which joists are too far gone to use once the decking has been removed. See photo.

Solution to Fungal Rot in Pressure Treated Wood

A two-step proprietary process has been developed which first kills the fungus within the wood both on the surface and below the surface. Called

Deep Wood Fungus Killer (DWFK), this material is composed of two agents... a powerful

surfactant and a biocide

compound.

According to the manufacturer, the biocide compound is an environmentally friendly chemical that protects against fungi, bacteria, and damaging pests like the Formosan termite.

The surfactant aids as a delivery system. It breaks down the surface tension between water molecules and allows the biocide chemical compound to move more deeply into the wood, killing fungus and bacteria as it is absorbed.

Background on How

Fungus Rots Wood:

Fungus secrets an enzyme which converts wood cellulose to wood sugar. This is what fungus consumes.

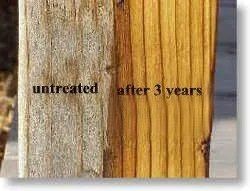

The result is wood rot as the wood cellulose is broken down, consumed and collapses. StoneWood prevents this process from occurring by establishing a permanent water proof barrier against fungus. StoneWood soaks into and fills the first few layers of wood cells and sets up a very hard, very light permanent barrier against fungal penetration. Simply put: Fungus cannot penetrate past the surface of pressure treated wood any more than mold can grow through the glass on your window. It can grow on the surface but it cannot penetrate the surface and grow into the interior of the wood.

Call

540-840-7243 with questions, to obtain pricing, or to place an order. You just need to know the area of your deck (length times width plus stairs).

STONEWOOD PREVENTS FUNGAL PENETRATION & DECAY:

StoneWood is a permanent internal wood protector. After first killing the fungus with DWFK, StoneWood is applied to the flooring and underside substructure of pressure treated wood projects such as decks, docks and boardwalks.

It is a space age material that fills several interior layers of wood cells with a barrier which seals and waterproofs the pressure treated walking surface and pressure treated underside sub-structure (framing). It prevents future fungal penetration, infection and decay indefinitely. It is also reportedly the 2nd lightest substance on earth.

It is also acid, salt and heat resistant and extremely light (2nd lightest substance on earth) In short, it stops aging from above or below a deck, dock or boardwalk by solidifying and hardening the first few layers of wood cells.

It is non-toxic, non-flammable, fumeless and will not harm aquatic life.

Once applied, it permanently fills several interior layers of wood cells with a quartz-like, crystalline substance and never needs to be applied again. It is "once and done". This "quartz-like, crystalline substance" prevents fungus from entering the wood similar to how glass prevents mold from getting through your window.

It is warrantied for life.

StoneWood not only preserves the wood against future rot and decay, it also provides a surface 300% more effective in the bonding of stains and paints.

Note: StoneWood is an internal wood protector...a SEALER... not a stain.

Please call 540-840-7243 with questions, or to obtain pricing or to place an order.

"Why can't I find more information on StoneWood? I have searched the internet and cannot come up with additional sellers or information on who makes it."

Great question! The simple answer is because if I published who makes it, my competitors would jump all over it and I would lose a very good competitive edge. StoneWood is an awesome product that we re-labelled. It is very well established and comes to my office from out of state with no label. I have known the owner of the factory for years and tested it myself many times... but I have private labelled (or white labelled) his product into StoneWood with his permission to make it proprietary and thereby protect my business.

BTW, this is a very common business strategy. For example, Sanyo probably did not make your television. Panasonic lets Sanyo put their label on them. I am told that Samsung manufactures many electronic components that are then private labelled and sold by others. When you buy a Dewalt power drill, you are actually buying a Black & Decker. Hmm. It is done all the time. Visit an Aldis grocery store and look around. Some items may look familiar but have a different name on the can or bottle. Chances are it is a white label.